Types of Leather Stitching

There's more to what makes our leather goods unique than the exotic leathers we specialize in. The craftsmanship of our products is only the best We pride ourselves in hand stitching wallets, sheaths, and other leather goods. But does machine sewing have its place in fine leather goods? Let's explore what makes these two techniques different and when we use each one.

Hand Stitching - The Leatherworker's Choice

Our hand stitched Yellowstone Bi-Fold Wallet

Our hand stitched Yellowstone Bi-Fold Wallet

Wait, can you sew leather by hand? It may seem like it would be difficult to pull a needle through leather - not only is it totally doable, but it's also an art that has been learnt and refined by thousands of artisans over centuries.

Hand stitching is about more than just creating another product, it's an art. Ask any of the leatherworkers in our shop, and they'll all tell you they prefer a hand stitched item to one sewn on a machine. Hand stitching is our preferred method for two reasons:

Craftsmanship

There's something special about knowing that an actual person crafted each stitch of the wallet you're carrying in your pocket or on the sheath you keep your favorite knife in. It's the difference between receiving a handwritten letter and an email — both get the job done, but one has a more personal, human touch. Each piece becomes a canvas, displaying the maker's adeptness to different techniques that contribute to the product in both functionality and aesthetic appeal. Hand stitching affords the luxury of working at a pace that supports attention to detail—stitches can be made to accommodate the leather's unique qualities, enhancing the product's overall functionality and feel.

Durability

Hand stitching uses a different technique than machine sewing. Hand stitching has roots stretching back centuries to ancient times, where it was used for its strength and durability in creating everything from clothing to armor. This technique has stood the test of time due to its unmatched ability to create robust and long-lasting seams. Because leather bends and softens over time, a stitch with some give and take to it will last longer than a machine stitch that could snap once the leather has been broken in.

How to Sew Leather By Hand

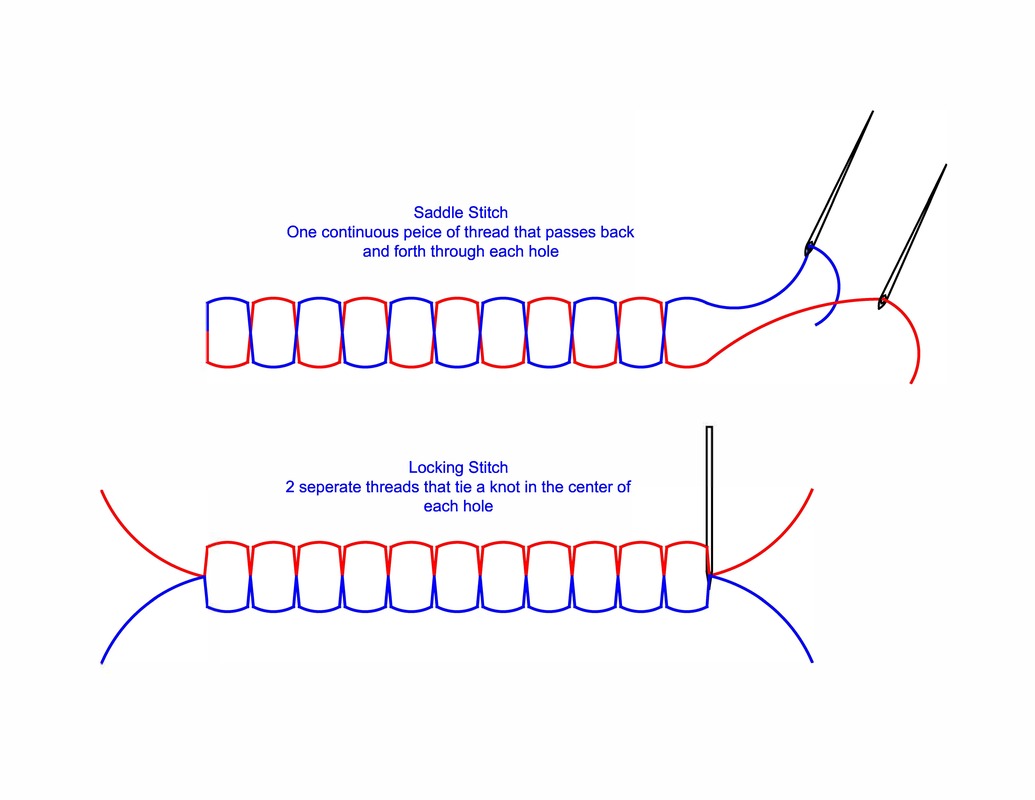

There are different types of stitching by hand, but most leathermakers use the saddle stitch. This technique is characterized by the use of two needles working in tandem at both ends of a single thread. This thread runs on both sides of the leather, passing through on both sides. The saddle stitch is still being used in the production of all sorts of leather goods — from actual saddles to wallets — today! This means that if one thread breaks, the whole thing won't unravel. Instead, it can be repaired and last even longer. Hand stitched leather goods also provide more flexibility than a rigid machine stitch. An awl is a tool with a pointed spike used in leatherworking to pierce holes in leather before hand stitching, ensuring the needle and thread can pass through more easily. Position your awl where you want your stitches to run, drive it through, then get to work sewing!

Hand stitching is about more than just creating another product, it's an art. Ask any of the leatherworkers in our shop, and they'll all tell you they prefer a hand stitched item to one sewn on a machine. Hand stitching is our preferred method for two reasons:

- Craftsmanship

- Durability

Craftsmanship

There's something special about knowing that an actual person crafted each stitch of the wallet you're carrying in your pocket or on the sheath you keep your favorite knife in. It's the difference between receiving a handwritten letter and an email — both get the job done, but one has a more personal, human touch. Each piece becomes a canvas, displaying the maker's adeptness to different techniques that contribute to the product in both functionality and aesthetic appeal. Hand stitching affords the luxury of working at a pace that supports attention to detail—stitches can be made to accommodate the leather's unique qualities, enhancing the product's overall functionality and feel.

Durability

Hand stitching uses a different technique than machine sewing. Hand stitching has roots stretching back centuries to ancient times, where it was used for its strength and durability in creating everything from clothing to armor. This technique has stood the test of time due to its unmatched ability to create robust and long-lasting seams. Because leather bends and softens over time, a stitch with some give and take to it will last longer than a machine stitch that could snap once the leather has been broken in.

How to Sew Leather By Hand

There are different types of stitching by hand, but most leathermakers use the saddle stitch. This technique is characterized by the use of two needles working in tandem at both ends of a single thread. This thread runs on both sides of the leather, passing through on both sides. The saddle stitch is still being used in the production of all sorts of leather goods — from actual saddles to wallets — today! This means that if one thread breaks, the whole thing won't unravel. Instead, it can be repaired and last even longer. Hand stitched leather goods also provide more flexibility than a rigid machine stitch. An awl is a tool with a pointed spike used in leatherworking to pierce holes in leather before hand stitching, ensuring the needle and thread can pass through more easily. Position your awl where you want your stitches to run, drive it through, then get to work sewing!

Hand Stitched Custom Sheaths

Almost every custom sheath we create is hand stitched by our founder, Francesca. Check out some of the amazing work she's done below! If you're interested in a custom sheath of your own, you can inquire here.

How Sewing Machines Work VS The Hand Sewn Saddle Stitch

Machine Sewing - The Efficient Alternative

The MKC Chef Knife Roll - Machine Sewn by Teton Leather

The MKC Chef Knife Roll - Machine Sewn by Teton Leather

Maybe you're asking yourself, "Can a sewing machine sew leather?" Totally understandable since it can be a thick and stiff material! But the answer is yes, a sewing machine is more than capable of sewing all kinds of leather.

There are some instances in which hand stitching is a bit too unrealistic. For production runs, our 12 employees may be working to get 400 knife rolls built in just one week. With these numbers, it's just not feasible for us to be hand stitching each item. Which brings us to some of the biggest benefits of machine sewing:

Efficiency

When you're looking to create a high volume of products, machine sewing is the way to go. This makes it the more popular option with most leather manufacturers if they have a tight schedule or high demand. A sewing machine means producing quality results in less time. But it's not all about getting things done as fast as possible. Using a machine can allow you to focus your time on other crucial aspects of leatherworking — detailed design is a key to superior, long lasting products.

Versatility

A machine can sew a variety of stitches and patterns. Once you know how to run a sewing machine, you can stitch almost anything. This also makes it a great option for growing businesses that need to produce high quality at a high volume. You can switch between numerous stitch patterns and lengths with the turn of a dial, catering to different design needs or leather thicknesses. It can easily create straight stitches, zig-zag for decorative finishes, or reinforcement stitches for high-stress areas. The pressure and tension of a sewing machine can be adjusted, making it fine tuned for working with leathers of varying weights and thicknesses.

How to Sew Leather on a Machine

Sewing leather on a sewing machine introduces you to the world of the lock stitch, a neat little dance between the top thread from the needle above and the bobbin thread below. This stitch locks itself in the middle of the leather, creating a secure and uniform seam with each pass. As you guide the leather, the machine performs its magic, intertwining the threads in a lock stitch as you go, binding your pieces together. It's a harmonious blend of machine efficiency and human guidance!

There are some instances in which hand stitching is a bit too unrealistic. For production runs, our 12 employees may be working to get 400 knife rolls built in just one week. With these numbers, it's just not feasible for us to be hand stitching each item. Which brings us to some of the biggest benefits of machine sewing:

- Efficiency

- Versatility

Efficiency

When you're looking to create a high volume of products, machine sewing is the way to go. This makes it the more popular option with most leather manufacturers if they have a tight schedule or high demand. A sewing machine means producing quality results in less time. But it's not all about getting things done as fast as possible. Using a machine can allow you to focus your time on other crucial aspects of leatherworking — detailed design is a key to superior, long lasting products.

Versatility

A machine can sew a variety of stitches and patterns. Once you know how to run a sewing machine, you can stitch almost anything. This also makes it a great option for growing businesses that need to produce high quality at a high volume. You can switch between numerous stitch patterns and lengths with the turn of a dial, catering to different design needs or leather thicknesses. It can easily create straight stitches, zig-zag for decorative finishes, or reinforcement stitches for high-stress areas. The pressure and tension of a sewing machine can be adjusted, making it fine tuned for working with leathers of varying weights and thicknesses.

How to Sew Leather on a Machine

Sewing leather on a sewing machine introduces you to the world of the lock stitch, a neat little dance between the top thread from the needle above and the bobbin thread below. This stitch locks itself in the middle of the leather, creating a secure and uniform seam with each pass. As you guide the leather, the machine performs its magic, intertwining the threads in a lock stitch as you go, binding your pieces together. It's a harmonious blend of machine efficiency and human guidance!

Pros & Cons of Hand Stitching VS Machine Sewing

|

Hand Stitching

Pros

Cons

|

Machine Sewing

Pros

Cons

|

Explore Hand Stitched Leather Goods

teton leather LLC

|

|

Copyright © 2015